SN500 Base Oil is a type of mineral oil that is commonly used as a lubricant[6]. It is a light-grade base oil at the upper end of the specifications for Grade I base oils[2][4]. SN500 has a viscosity of 10.1-11 cSt at 100°C and 94-98 cSt at 40°C[1]. It is the most widely used base oil[1].

SN500 is mainly used in lubricant production[2][4]. It is also used in rubber processing as a processing oil[3]. SN500 has undergone solvent refining to remove impurities[5]. It is produced and sold by various companies worldwide, including Sepahan Oil Company, Behran Naft Pars, and DYM Resources[1][5].

Origin and Production Process

SN500 Base Oil is produced by refining crude oil[3][5]. The production process involves distillation, solvent refining[3], and solvent and wax extraction processes[2]. The crude oil is heated and separated into several fractions[5]. The SN500 Base Oil is then highly refined through a process of distillation that removes impurities such as water, dirt, and other contaminants[4]. The refining process is finished by hydrogenation[6]. The SN500 Base Oil is a base oil that has been produced since the 1930s[1].

Distillation and Hydroprocessing

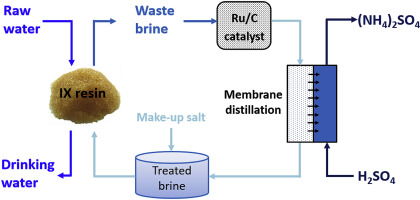

The production process of SN500 Base Oil involves distillation and hydroprocessing. Here are the steps involved in the production process of SN500 Base Oil:

1. Vacuum distillation: The oil from the gasoil stripper is sent to vacuum distillation to recover vacuum distillate oil fraction from “heavier than” contaminants[1].

2. TFE and Fractional continuous distillation: The oil is then subjected to TFE and fractional continuous distillation to generate different base oil distillates[2].

3. Refining: The base oil distillates are then refined for good color or even watercolor base oil[2].

4. Hydrotreatment: The heavy hydrocarbon stream is subjected to hydrotreatment and selective hydrogenation at optimized process conditions[3].

5. Hydrogenation: The mixture of deasphalted bottoms and unpressable distillate is combined with fresh hydrogen and recycled hydrogen flowing through a conduit. The mixture is then hydrogenated to remove toxic nitrogen and sulfur compounds, as well as other oxides present in the chemical[4][5].

6. Oil distillation under reduced pressure: The final step is oil distillation under reduced pressure, which is done until 250ºC[6].

The above steps result in the production of highly refined SN500 Base Oil.

Here are the properties of SN500 Base Oil:

– Viscosity Index: SN500 Base Oil has a relatively high viscosity index[3][6]. Its viscosity is 10.1-11 cSt at 100°C and 94-98 cSt at 40°C[1].

– Flash Point and Fire Point: The flash point of SN500 Base Oil is typically around 216-240°C[3][4][5]. The fire point is the temperature at which the oil will ignite and burn continuously, and it is typically higher than the flash point[5].

– Pour Point: The pour point of SN500 Base Oil is around -9°C to -12°C[3][4][6]. It is the lowest temperature at which the oil will flow[3].

– Oxidation Stability: SN500 Base Oil has good oxidation stability[1]. It means that it resists oxidation and degradation when exposed to air and high temperatures[1].

– Sulfur Content: The sulfur content of SN500 Base Oil is typically low[1][2]. It is an important property because sulfur can cause corrosion and wear in engines and machinery[1].

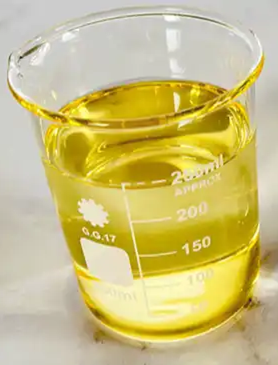

– Color and Clarity: SN500 Base Oil has a light color and good clarity[1][2][4]. The color is typically 2.5-3.0 ASTM[4].

– API Gravity: The API gravity of SN500 Base Oil is not mentioned in the search results.

Applications of SN500 Base Oil

– Automotive Lubricants

– Engine Oils

– Transmission Fluids

– Hydraulic Fluids

– Industrial Lubricants

– Gear Oils

– Metalworking Fluids

– Greases

– Other Applications

– Rubber Processing

– Ink Manufacturing

– Adhesive Formulation

SN500 Base Oil is a versatile product that finds its applications in various industries. Here are some of the applications of SN500 Base Oil:

– Automotive Lubricants: SN500 BaseOil is used in the production of various automotive lubricants, including engine oils, transmission fluids, and hydraulic fluids[1][2][4].

– Industrial Lubricants: SN500 Base Oil is also used in the production of industrial lubricants, including gear oils, metalworking fluids, and greases[1][4].

– Other Applications: SN500 Base Oil is used in other applications such as rubber processing, ink manufacturing, and adhesive formulation[1].

SN500 Base Oil is a premium mineral oil that is often used as a lubricant in a variety of industrial applications[5]. It is a light-colored, low-viscosity oil made from crude oil[3]. SN500 Base Oil is a highly refined oil that is produced through a process of refining crude oil[4]. It is a common quality base oil product that is categorized in Group I[6].

Advantages of SN500 BaseOil

– Thermal Stability

– Oxidation Resistance

– Enhanced Lubrication

– Improved Viscosity Control

– Compatibility with Additives

– Environmental Benefits

SN500 Base Oil has several advantages that make it a popular choice in various industries. Here are some of the advantages of SN500 Base Oil:

– Bright color: SN500 Base Oil has a bright color, which makes it suitable for use in applications where color is important[1].

– Favorable oxidation and thermal stability: SN500 Base Oil has good oxidation and thermal stability, which means that it resists oxidation and degradation when exposed to air and high temperatures[1]. SN500 BaseOil

– Low volatility: SN500 Base Oil has low volatility, which means that it does not evaporate easily[1].

– Excellent viscosity stability: SN500 Base Oil has excellent viscosity stability, which means that it maintains its viscosity over a wide range of temperatures[1].

– Good viscosity: SN500 Base Oil has a good viscosity, which makes it suitable for use in various lubricant applications[3].

– Suitable replacement for virgin base oil: Recycled SN500 Base Oil has excellent chemical and physical properties, making it a suitable replacement for virgin base oil[2].

– Versatile: SN500 Base Oil is a versatile product that finds its applications in various industries, including automotive, industrial, rubber processing, ink manufacturing, and adhesive formulation[1].

Overall, SN500 Base Oil is a high-quality base oil product that offers several advantages, including good oxidation and thermal stability, low volatility, and excellent viscosity stability.

there is the information on quality standards and testing for SN500 Base Oil:

ASTM and API Standards:

– SN500 Base Oil is subject to various ASTM and API standards to ensure its quality and performance[3][5].

– ASTM D445 is used to measure the kinematic viscosity of SN500 Base Oil[5].

– API SN is a standard for engine oils that specifies the performance requirements for SN500 Base Oil[1].

Testing Methods:

– SN500 Base Oil is tested using various methods to ensure its quality and performance[3][5].

– ASTM D445 is used to measure the kinematic viscosity of SN500Base Oil[5].

– Other tests include flash point, pour point, color, and sulfur content[1][4].

Quality Assurance in Base Oil Production:

– Quality assurance is an important aspect of base oil production[3].

– Each and every grade of base oil must meet the highest quality standards and be fully compliant with ISO, ASTM, and EU international standards[3].

– Quality assurance involves testing the base oil at various stages of production to ensure that it meets the required specifications[3].

– The specifications of SN500 BaseOil may vary depending on the manufacturer and the intended use of the oil[4].

Overall, SN500 BaseOil is subject to various ASTM and API standards, and it is tested using various methods to ensure its quality and performance. Quality assurance is an important aspect of base oil production, and it involves testing the base oil at various stages of production to ensure that it meets the required specifications.

– The base oil market is subject to various supply and demand factors, including feedstocks, energy costs, and geopolitical uncertainties[1].

– The Group II market cooled off in Q4 2022, following the downturn for domestic Group I base oils[1].

– A Chinese state-owned refiner is expected to continue exporting regular volumes of more than 10,000 tonnes per month of Group I SN150 and Group II 150N in H1 2023 due to sluggish domestic demand[1].

Emerging Trends:

– The base oil market is subject to emerging trends, including the shift towards Group II and III base oils, which offer better performance and environmental benefits[1][5].

– The demand for high-quality lubricants is increasing, which is driving the demand for high-quality base oils such as SN500 BaseOil[5].

– The use of recycled base oils is also increasing, which is driving the demand for recycled SN500 Base Oil[2].

Future Prospects of SN500 Base Oil:

– The future prospects of SN500 Base Oil are positive, as it is a versatile product that finds its applications in various industries[1].

– The demand for SN500 BaseOil is expected to increase in the future, driven by the increasing demand for high-quality lubricants and the shift towards Group II and III base oils[1][5].

– The use of recycled SN500 Base Oil is also expected to increase in the future, driven by the increasing demand for sustainable and environmentally friendly products[2].

– However, the future prospects of SN500 Base Oil are subject to various supply and demand factors, including feedstocks, energy costs, and geopolitical uncertainties[1].

Environmental and Regulatory Considerations for SN500 Base Oil are as follows:

Environmental Impact:

– The production and use of SN500 Base Oil can have an environmental impact, including air and water pollution[1][3].

– However, the impact can be reduced through the use of sustainable practices and the recycling of used base oils[2][5].

Sustainability Practices:

– Sustainable practices can be used in the production and use of SN500 Base Oil to reduce its environmental impact[5][6].

– These practices include the use of renewable energy sources, the reduction of waste and emissions, and the recycling of used base oils[2][5].

Regulatory Compliance:

– SN500 BaseOil is subject to various regulations and standards to ensure its safety and environmental compliance[1][3].

– These regulations include safety, health, and environmental regulations specific to the oil and gas industry[1].

– SN500 Base Oil can also be subject to regulations related to environmentally acceptable lubricants[3].

Overall, SN500 Base Oil is subject to various environmental and regulatory considerations, including its environmental impact, sustainability practices, and regulatory compliance. Sustainable practices can be used to reduce the environmental impact of SN500 Base Oil, and it is subject to various regulations and standards to ensure its safety and environmental compliance.

Conclusion

In conclusion, SN500 base oil plays a vital role in the lubricants industry due to its exceptional properties and versatility. Its wide range of applications, coupled with its advantages and compliance with quality standards, makes it a preferred choice for various industries. As the demand for high-quality lubricants continues to rise, SN500 base oil is expected to maintain its prominent position in the market.